Revolutionizing the Automotive Industry with Mogul Nonwovens

The automotive industry is at a pivotal juncture, with manufacturers relentlessly pursuing innovations to reduce vehicle weight, cut down costs, and ensure safety—all without compromising on quality and performance. At the forefront of this revolution are non-woven materials, offering an unparalleled blend of benefits specially tailored for automotive applications.

Mogul, a leading name in nonwoven material production, is steering this transformation with its specialized product range, including the notable cross-lapped spunlace and MOPET product line, acclaimed for its burn resistance and adherence to US FMVSS 320 standard. These materials are not only revolutionizing the traditional automotive component landscape but are also redefining the industry’s approach to design and manufacturing.

Key Benefits of Nonwovens in the Automotive Industry

Nonwovens bring forth an array of advantages to the automotive sector, essential for the modern-day demand for lighter, safer, and cost-effective vehicles. The key benefits include:

- Weight Reduction: Nonwovens offer significant weight advantages, crucial for enhancing fuel efficiency and reducing emissions.

- Cost-effectiveness: The production and integration processes of nonwovens are more cost-efficient compared to traditional materials, enabling manufacturers to optimize expenses.

- Versatility: With a broad spectrum of applications, nonwovens cater to various needs within the automotive industry, from interior trimming to safety components.

- Safety Enhancements: Products like Mogul’s MOPET exhibit superior burn resistance, essential for ensuring passenger safety against interior fires.

Leading Applications of Nonwovens in Automotive Design and Manufacturing

Headliners

Cross-lapped spunlace nonwovens have emerged as the material of choice for automotive headliners, imparting aesthetics, durability, and superior acoustic properties.

Acoustic Insulation

Nonwovens play a critical role in acoustic insulation, effectively absorbing and dampening noise, thus enhancing the in-cabin experience for passengers.

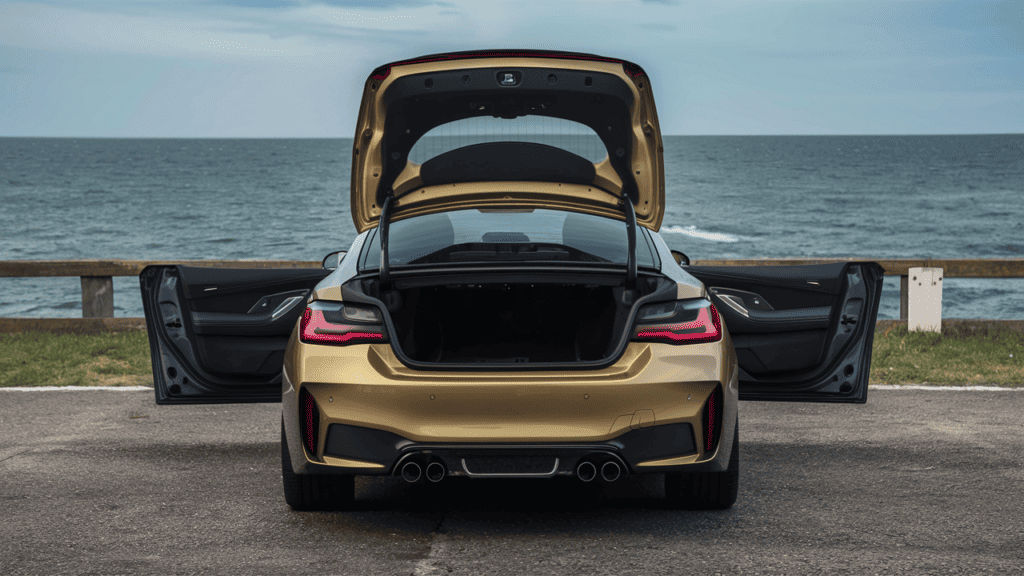

Interior Fabrics

The versatility of nonwovens allows for their application in various interior fabrics, including seat coverings, door panels, and more, offering comfort and style.

Secondary Carpet Backing

Nonwovens serve as an excellent secondary backing for automotive carpets, providing stability, durability, and a refined finish.

Airbags

Safety is paramount, and nonwovens contribute to this quest by being employed in the construction of airbags, offering reliability in times of need.

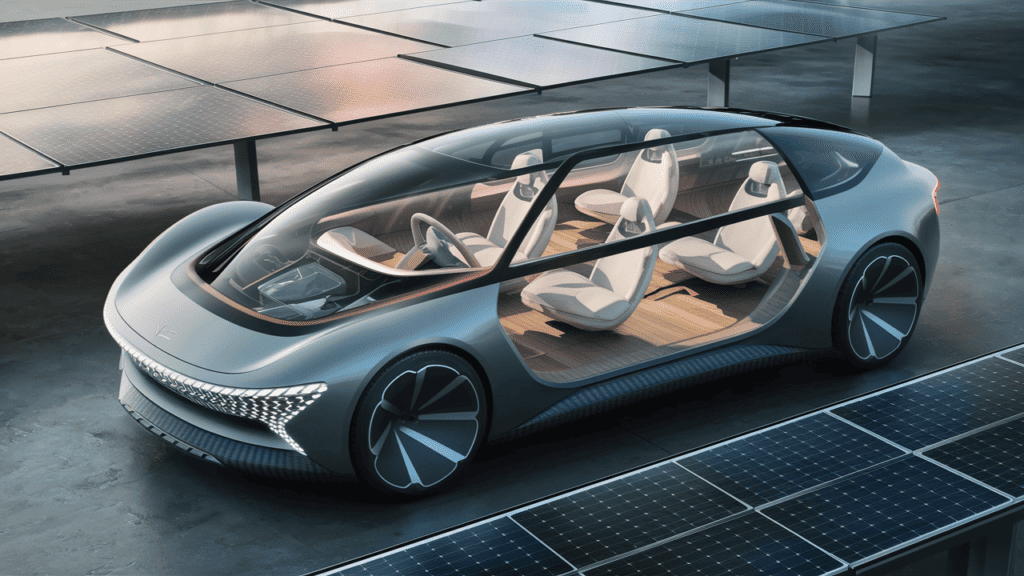

Innovative Materials for a Sustainable Future

With the integration of nonwovens, the automotive industry is not just advancing towards a more sustainable and efficient future, but it is also opening doors to innovative design possibilities and enhanced safety features. Mogul’s commitment to excellence and adherence to safety standards exemplify the potential of nonwovens in transforming automotive manufacturing for the better.

We invite you to explore the world of nonwovens with us, where innovation drives every application, paving the way for the next generation of vehicles. Discover how Mogul’s nonwoven solutions can elevate your automotive projects, delivering performance, safety, and sustainability in every fiber.